How to program BMT series outside diameter tool holder? Is it difficult?

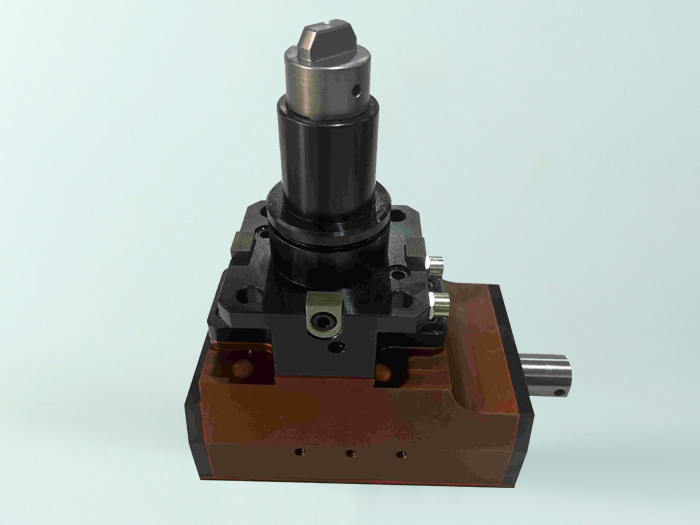

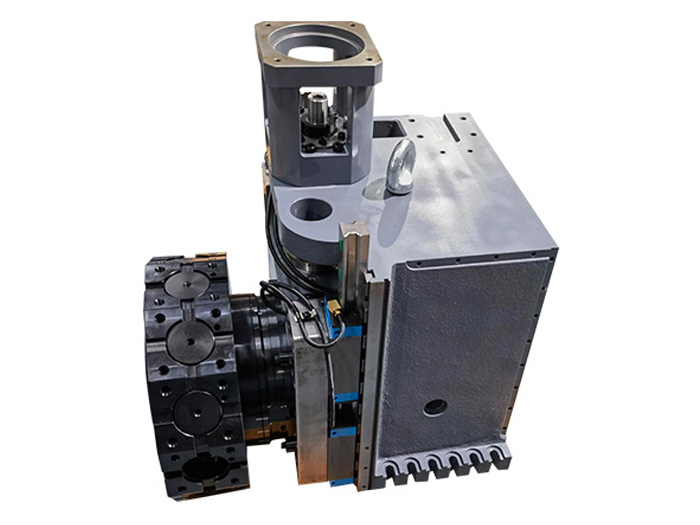

BMT40 outside diameter tool holder programming is not very difficult, the difficulty is not very high, because this tool holder is a multi-axial movement. Therefore, in the process of using a fixed tool holder, the programming will be simpler, and the difficulty is not very high. Fixed cutter holder in the purchase need to pay attention to the quality of the manufacturer's products, Bowei is a lot of factories cooperation object, this factory has more experience. Bowie has always been more loved by the factory, has more than 10 years of processing experience, has provided products and services for many large factories.

How much lathe fixed tool holder speed?

The fixed cutter base speed reaches 15,000 RPM, which is indeed a high production accuracy. The fixed tool holder products produced by Bowei are very good, and the company has created its own patent in the case of foreign product patents, polymer nano-ceramic coating technology, which effectively improves the service life of the fixed tool holder. Fixed tool holder must choose Bowei, the company has more than ten years of precision motor parts processing experience, accumulated a very deep technology. In the product does do very well, after-sales service is also very good, if there is a need to consult the company's customer service staff.

When we choose and fix the left and right hand of the fixed tool holder, we choose the left or right hand tool holder mainly according to the rotation direction of the spindle, the pressing block and the cutter head device. Bowe said that if the fixed tool holder workpiece to be machined is above or below the tool tower, the axial fixed tool holder can be selected. If the machining center of the workpiece is on both sides of the tower, the radial cutter holder can be selected. The radial fixed cutter holder has no left or right radial cutter holder, and both sides can be used. Bowe said that if the workpiece processing position of the fixed tool holder is on the left and right sides of the tool tower, the axial fixed tool holder should be selected, and if the processing position is on the upper and lower sides of the tool tower, the radial fixed tool holder should be selected.

Home

Home

Product

Product

News

News

Contact us

Contact us