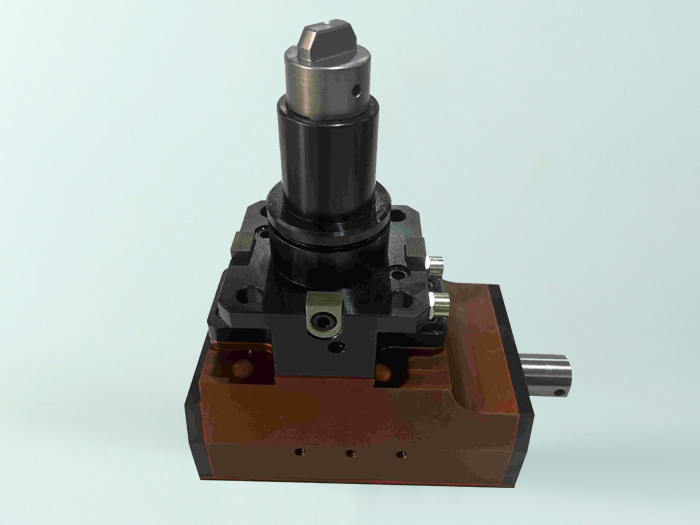

BMT Series 40 boring tool holder

1, turning tool installation:

(1) The turning tool can not extend the tool holder too long, and should be extended as short as possible. Because the tool extends too long, the rigidity of the tool bar is relatively weakened, and it is easy to produce vibration when cutting under the action of cutting force, so that the surface of the workpiece is not smooth. Generally, the length of the tool extension does not exceed 2 times the thickness of the tool bar.

(2) The height of the turning tool tip should be aligned with the center of the workpiece. If the tool is installed too high or too low, it will cause the change of tool Angle and affect the cutting. According to experience, when the rough turning is round, the turning tool can be installed slightly higher than the workpiece center; When turning the outer circle, the turning tool can be installed slightly lower than the center of the workpiece, which depends on the size of the diameter of the workpiece to decide, whether installed high or low, generally can not exceed 1% of the diameter of the workpiece. For example, when the tip of the turning tool is higher than the axis of the workpiece, because the position of the turning plane and the base surface changes, the front Angle increases and the back Angle decreases; otherwise, the front Angle decreases and the back Angle increases. The skew of the tool installation has a great influence on the main and secondary deflection angles, especially when the thread is turned, it will cause the error of the tooth half Angle. Therefore, the correct installation of the turning tool is an important step to ensure the processing quality, reduce tool wear and improve the service life of the tool.

(3) The gasket for the loading knife should be flat, and the thickness of the gasket should be used as much as possible to reduce the number of pieces, generally only 2-3 pieces. If the number of pads is too many or uneven, it will cause the turning tool to vibrate and affect the cutting. And make each gasket under the tool bar, the front end is in line with the edge of the tool holder.

(4) After the tool is installed, the tool holder screws should be tightened, generally two screws should be tightened. When tightening, rotate and tighten one by one. At the same time, it should be noted that a special wrench must be used, and casing is not allowed to be added, so as not to cause excessive force and damage to the screw.

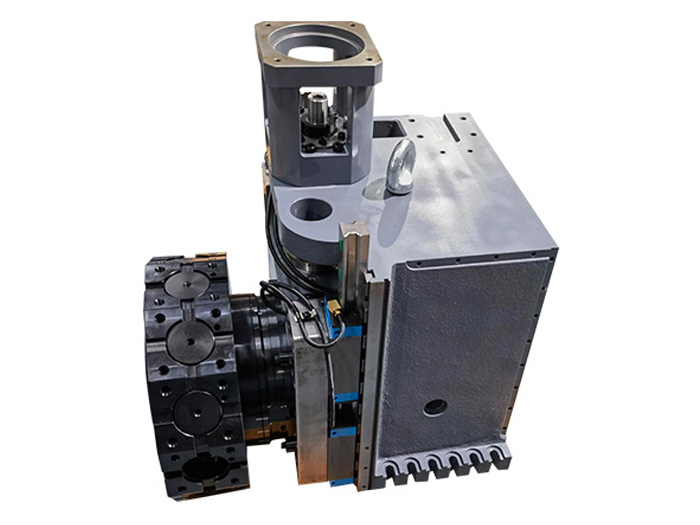

2. Boring tool holder:

Before the execution of the machining program, the tool point of each tool is adjusted so that it coincides with an ideal reference point as much as possible, this process is called tool alignment. The ideal reference point can be set on the tip of the reference knife, or it can be set on the positioning center of the tool (such as the intersection point of the cross line in the optical tool mirror). The knife is generally divided into manual knife and automatic knife two categories. At present, the vast majority of CNC lathes (especially lathes) adopt manual tool setting, and the common methods include positioning tool setting, optical tool setting, and test cutting tool setting.

首页

首页

产品中心

产品中心

新闻动态

新闻动态

联系我们

联系我们